|

deutsche Version

deutsche Version

Test and Handling Systems

We develop and construct for our customers complete test stations and test equipments for

the development and production of electronic and, most of all, optoelectronic devices and

products. Up to the specifications and capacity we develop manual- , semi- or fully -

automatic test stations. For these equipments we develop and construct all parts of

mechanics, electronics and software in our own company. Therewith we are able to provide

optimized delivery times with technical faultless and financially optimized solutions.

At the following examples, the specific characteristics will be highlighted. With this widespread

experiences and know how, we are able to provide solutions even for difficult tasks. Our project names

are mentioned in brackets.

Automat for testing of laser modules

System for contacting of DIMM memory modules

Controller for LED taping

Add-ons for wafer probers

SONET (OC48)

Pulse-Laser (PL90)

Sensor- surveying (ALBA, IRIS, PREA and others)

MOST ® Transmitter and Receiver (OBIM)

Rattle-Factor (RAFA)

IR-Receiver (SFH)

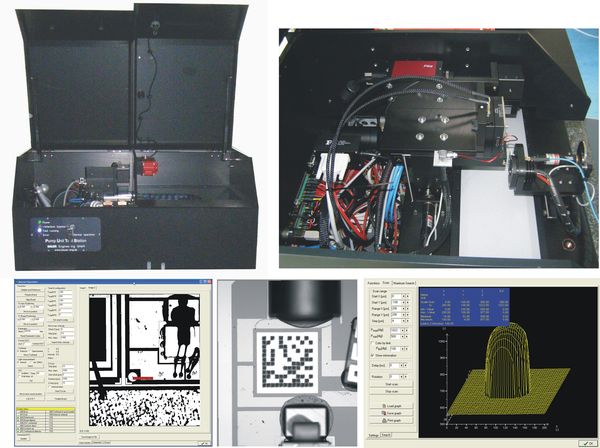

Automat for testing of laser modules

Automatic handler for testing of laser modules. The challenge of this test station is the exact positioning (±1µm) of the DUTS as

well as of an mirror that is temporarly inserted in the beam path.

- Automated position recognition by vision system.

- Accurate DUT positioning and contacting using precise motor controlled stages.

- Fast XY positioning of a mirror that is placed in the beam path using piezo translators.

Active alignment of the mirror to the position with optimum optical power output.

- Accuracy: ±1µm

- Temperature control of the DUTs by TECs in the ranage of 20°C to 60°C.

- Execution of optical measurements along the beam path(Z). Measurements are done on-fly with synchronized position correction (XY).

- Reading of the DUT's 2D-codes with vision system.

- DLL-Interface for 32bit-Windows for integration of the handling system into superordinated test system

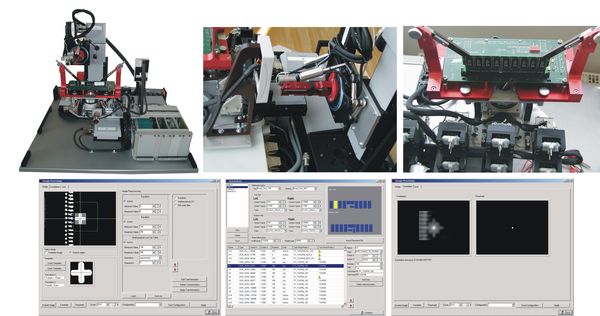

System for contacting DIMM memory modules

This system is used for contacting of DIMM memory modules by special test heads in order to execute clock skew and jitter measurements.

- Positioning in X, Y, Z-direction, additional rotation of test head.

- Rotating table for module fixture to measure front and back side.

- Position recognition using vision system.

- Automated exchange of the test heads, integrated test head stock.

- Recognition of test head type by RFID.

- Data bases for different module types and test heads.

- DLL-Interface for 32bit-Windows for integration in customer's analysis system.

Controller for LED taping

System for taping and sorting of LEDs. BAUER Engineering has develop the electronics and the realtime embedded software for this system.

- Pickup of the LEDs by vacuum pickup tool and transfer to carrier tape

- Cycle time < 200ms

- Controlled by embedded PC with real time operating system

- Feature for digital recording and analysis of the mechanical movement of the pickup tool

- Recognition of empty cavities by light barrier

- Controlling of heated stamp for sealing

- Communication with superordinates SPS handler (digital I/O) and to host system (TCP/IP)

- Versions working as bin sorted or transfer station

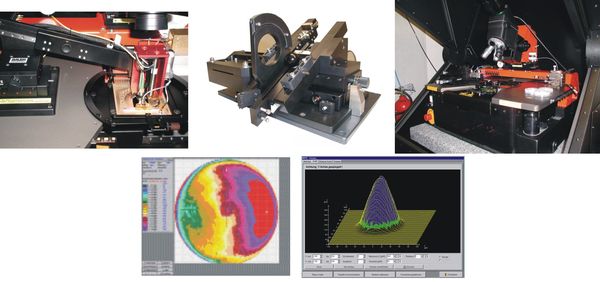

Add-ons for wafer probing stations

We habe developped a series of add-ons for standardized equipment for wafer probing.

- System for micropositioning of an optical fiber with an accuracy of ±1µm.

Special evaluation and test electronics for fast power measurements.

Real time software for embedded systems for fast active alignment of the optical fiber.

- Optical systems for coupling of emitted light into optical fibers.

- Electronics for time critical execution of contact checks.

- Design and coding of the PC based test and control software.

Sensor-Surveying (ALBA, IRIS, PREA and others)

The number of optoelectronic sensors is growing fast. We already have developed and constructed a wide

range of special test stations for such kind of sensors. The pre-condition for such projects is a faithful

co-operation with our customers, because of the necessary knowledge of design and functionality of the

sensor to develop such test stations. Secrecy of such confidential information is absolutely compulsive to us.

Our developed and constructed equipments normally simulate the dedicated real conditions and the items and

units to measure. Additionally there can be done some other measurements like surveying the beam properties,

the EMI-stability or the attitude of temperature.

These measuring systems produce high demands to the mechanics, system safety, long termed stability and

the device handling.

SONET (OC48)

Surveying lasers and diodes, used for data transfer on single mode fibers up to 10Gb/s, causes high

demands to the contacting system due to mechanical, electrical, optical and thermal coupling and

connection. It was necessary for this project to develop specialized test contacting systems,

granting reproducible measurements.

Puls-Laser (PL90)

For optical distance measuring, there are used some power lasers with up to 100&nbps;W light power, which are

able to send pulses of some few nanoseconds. For this reason it is necessary to switch driving current of about

50 A extremely fast and accurately. Additionally to the pulse generation it is necessary to have a light

power to time ratio measurement device. Furthermore there are high demands to the measurement device on

stability and the ability to calibrate.

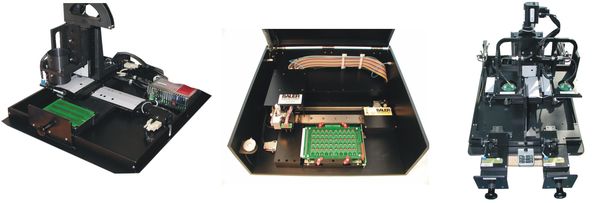

MOST ® Transmitter and Receiver (OBIM)

The automotive interior environment is fitted with a growing number of infotainment devices like radio,

phone, navigation device or CD player, with the increasing need of inter linking these devices. For this

demand, the automotive and supplier industries developed the MOST®-Bus in closely co-operation. It is an

optical ring bus with POFs (plastic optical fibers).

To test the send and receive devices, we develop and construct special components and equipments,

checking the switching properties and behavior of these sending and receiving devices. The decisive point

is to realize conversion from electrical in optical signals and vice versa, without any negative time

critical interference.

Rattle-Factor (RAFA)

A test station for characteristic lines of cord set semiconductor laser was upgraded for receptacle versions

including a measurement device for light coupling with synchronous jiggling (rattling) the connector system.

Additionally, the eye safety is tested on this equipment. To be independent of a laser's potentially existing

squint angle, this measurement is solved with an infrared camera and dependent image processing.

IR-Empfänger (SFH)

These components, which are installed in a lot of infrared remote controller, are produced in a huge amount.

BAUER Engineering develops and constructs semi and fully automatic test stations with high capacity,

according for those devices. In these devices, control signals with adjustable light power and frequency

are generated and the device's switching properties and behavior are determined.

|